Berliet in Algeria: more than a story, strong ties

- COCKPIT

- Jul 8, 2023

- 10 min read

Updated: Nov 5, 2025

Berliet, the French truck brand shares a large part of its history with Algeria, not only with its factory located in Rouïba (Algeria), but much more:

Marius Berliet built his first single-cylinder engine in 1894 and his first car in 1895 in a lean-to in the family home. In 1899, he created Automobiles Marius Berliet, commonly known as Berliet. It then manufactures automobiles (until 1939, and will continue exclusively as a manufacturer of industrial vehicles).

On July 1, 1905, American Locomotive Company (ALCO), which wished to diversify into the automobile, chose Berliet to acquire a 3-year license for the manufacture of three models of Berliet cars. This financial windfall will allow Berliet to embark on new projects.

In 1906, Berliet therefore began to produce trucks and sent them to Algeria for testing, which ended in failure. Disappointed, Marius Berliet wants to erase the failure and at the same time prove that his gasoline trucks are very reliable. He is preparing a return to Algeria with a new, stronger ambition by organizing a North - South crossing, something that has not yet been done.

It took 3 years for this to happen, so it was in 1909 that a Berliet truck loaded with three tons of freight linked Algiers to Laghouat for the first time, a journey of 330 km. A ten-day journey to make the round trip, sometimes with the support of the population to help it move forward in the sand by means of wooden planks slipped under its iron-rimmed wheels. In Médéa, he manages to climb 12 km of coast at the speed of 9 km/hour. No truck having yet gone as far as Laghouat, its arrival is an event that promotes the notoriety of the Lyon manufacturer.

1909 is also the year in which Berliet inaugurates its first branch in Algiers, a lasting presence in Africa and in 1912 Berliet opens a second branch in Oran.

World War I broke out in 1914 and Berliet concentrated on military vehicles in Europe while its activity in Algeria was put on hold.

Between the two wars, business picked up and Marius Berliet focused his efforts on setting up a solid network of dealers equipped with spare parts and professional repair resources. Algeria represents an important outlet for cars and especially trucks used both for transporting goods and for transporting people. Berliet demonstrates that North-South links can succeed.

Berliet undertakes African crossings

In 1926, Mission Sahara Niger, the first crossing with three-axle vehicles, three Berliet VPD 6 × 4 models successfully carried out the Algiers - Gao mission with 3,000 kg of cargo and 22 passengers.

In 1932, it was the turn of the Diesel mission in the Sahara to link Algiers - Gao there and back.

The World War comes to its second act, which plunges Berliet back into his military activities.

Rebelote in 1945, Berliet found himself with surpluses, it was necessary to demonstrate savings and performance.

In 1950, Berliet released the GLR8, a modern truck which was to be the avant-garde of the brand, the brand then wanted to show that this truck was capable of covering considerable distances and difficult roads in complete reliability and comfort. Two prototypes of the "colonial" GLR were built and entrusted to the Compagnie Saharienne Automobile managed by René Deviq in Touggourt, Algeria.

We use the old recipes for this and organize a new Algiers Abidjan expedition, a journey of 7500 km.

Maurice Berliet was on board to see the perfect mechanical adaptation of the vehicle to its use. It is this material which, equipped with wide tires, gradually equipped all the military transport units in the Sahara.

Thanks to this, Automobiles M. Berliet sells 10 to 12% of its production in Algeria and in 1953 a new branch is built in Oran. In 1955, in Algiers, Berliet expands.

Berliet factory in Algiers

Berliet Truck Tests in the Algerian Desert

In October 1959, the Ténéré mission set off from Algiers. The vehicles leave the Berliet branch installed on rue Hussein Dey on March 6, 1959. Mr. Conty drives the first Land Rover. Mr. Rogniez, who is not on his first Saharan mission, is at the wheel of the GBC 8 M 6x6 white fridge.

Berliet expands in Algeria and between 1959 and 1960, two new branches are built, in Constantine and Ouargla.

With a rich network of 35 dealers, brand penetration reaches 70%.

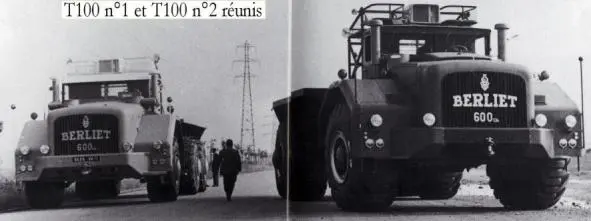

A Giant for oil research: The T100 the largest truck in the world is built

From 1952, France began a new dynamic of oil prospecting in Algeria, it was modernized and the estimates were promising. New needs were felt. In 1954, hydrocarbon deposits were discovered in the Algerian Sahara. Invited by the director of Shell to go to El-Goléa (now El Menia) at the end of 1956, Paul Berliet “finds that the vehicles available to the company are not suitable. The director of Shell asks to offer him equipment that could help him in prospecting and exploitation. Transported by plane from Timimoune to their base in the Western Grand Erg, Paul Berliet discovers the barchanes, large crescent-shaped dunes, and the gigantic road works necessary for their crossing by the semi-trailers which transport the prospecting equipment. petroleum”.

Paul Berliet continues: “When I saw the problems posed by the dunes in the Sahara, I decided to do the T100. Finally we showed what we could do: the biggest truck in the world! I entrusted André Billiez with the development of a machine capable of carrying a 50-tonne load in the dunes without the need to build an extremely expensive track.

I took the biggest tires available at the time, chose the Cummins engine which offered the best compromise between power, lightness and performance in the target power range. The 600 hp of the first engine was insufficient, and we went to 700 hp but a power of 1000 hp would have been desirable”.

Designed and manufactured in 9 months to meet the transport needs of indivisible masses of more than 40 tons of oil exploration, the gigantic T100 could cross the dunes of the Grand Erg Oriental without requiring the development of a track.

The T100 n°1 was presented at the Paris Motor Show in October 1957 and the n°2 was sent to the Sahara, joined in December 1957 by the n° 1. The two T100 present in Algeria remained in the Gassitouil but were not used for very long because very quickly easily accessible gas deposits were discovered by the Algerians who lost interest in the Western Grand Erg. To extend their oil research after independence, the Algerians acquired American equipment.

Two copies were used in the Sahara in Gassi-Touil. One was kept by the Algerians, the other is part of the collection of the Berliet Foundation after Algeria donated it to them in 1981.

Two other T100s were built, but with all other configurations and needs: T100 n°3 was a 6x4 vehicle equipped with a Marel tipper for use in the uranium mines of Limousin, and T100 n°4 was designed for the US market. These two copies no longer exist.

Tyres: “the pressure of the dromedary’s foot”

When it left the factory, it was fitted with “public works” type tires. From January 1959, it was fitted with Michelin Tubeless “special sand” 37.5/33 XR tires, 2.20 m in diameter and nearly 1 m wide. Each tire weighs more than 950 kg but has less than 1 kg/m² of ground pressure, or 1 kg/cm² for a total weight of 100 tonnes.

Although the GVW is 101 tons, the tires are calculated to support 120. The result is mentioned in a report of February 6, 1959: T100 tire track depth is 10 cm and it crosses slopes in sand up to 20%…”.

The wheel of the T100 is taller than a normal sized man. The empty weight of this truck is 100 tonnes and its maximum speed reaches 34 km/h. Its height is 5 m as is its width, while its length is 15 meters and was the largest truck in the world at the time of its manufacture.

Berliet and the integration of Algerians

On September 6, 1954, two months before the outbreak of the Algerian war, the director of the branch of the Berliet factories in Algiers sent a letter to headquarters without illusions about the future of French Algeria. He considers that, “despite the apparent calm” which reigns in Algeria, everything is to be feared from the evolution of the Muslim populations, and he invites the management of Vénissieux to “very quickly take this into account”. Noting that "the indigenous clientele, whose purchasing power is steadily increasing", represents "a daily higher percentage" of sales, he continues: "We must therefore organize ourselves not only to prospect more and more of them, but also to make us understand her and inspire her with all the necessary confidence. [...] These considerations lead us to foresee in the very near future, at the Algiers branch, a "Muslim Relations Department" which [...] would include a group of educated and educated Muslim salespeople (Arabs and Kabyles) (and there are!). »

Paul Berliet approves the measure. In a note to staff, he wrote: "Obviously we would personally have to react against the prejudices of our European collaborators if we hired a Muslim salesman who could possibly be more educated than them" and who would not obtain from his colleagues "the consideration and impartiality to which he would be entitled".

Later, the boss of the heavyweight group goes even further. He set up a production unit on the spot from which trucks would come out which, derisively, the competitors would baptize “Kabyle trucks”: in fact, 80% of the factory's employees were Muslims.

“We don't believe in the future of the myth of exporting to underdeveloped countries,” declared Paul Berliet a little later, on the occasion of a conference reproduced in the company newspaper Berliet Informations. America before us made the cruel experiment of it. We will not long continue to buy ore from the poor at prices that fluctuate too much, in order to resell to them transformed products in which we will have incorporated a standard of living and high government overheads that they cannot and will not pay. In order not to lose everything tomorrow, it is necessary today, in a painful effort, to teach them to work, to abandon simple work on heavy and bulky elements to them no longer to keep, as and when they will rise in the technique, that the complicated parts justifying considerable investments, and tomorrow perhaps only the research, the design and the development. »

This language was explicitly part of the preparation for Algerian independence. Indeed, at a time when 49% of French people still declared themselves supporters of French Algeria, Paul Berliet made no secret of having negotiated with the Provisional Government of the Algerian Republic (GPRA) the subsequent conditions for the operation of his factory. Later, it was to him that the People's Republic of China would turn to equip the country with a truck industry. A well-understood "Third Worldism", and an effort of strategic forecasting that we must now repeat, in a completely different context, both for Indochina and for Algeria.

Berliet begins its first industrial establishment in Algiers

In 1956, oil gushes out in the Sahara! There is a growing need for vehicles of all kinds. Medium weights for prospecting, heavy goods vehicles for the transport of survey equipment, tubes that will constitute the "pipe line", tanks for the evacuation of the first oil... 130 Berliet are sent to Algeria that year. The following year this figure will rise to 250. Faced with this skyrocketing demand, also before the desire expressed by the Government to see the industrialization of Algeria develop, where there is no shortage of local labor, the large firm from Lyon took the first initiative to move to North Africa. The first French assembly line on the Continent is born in Hussein-Dey, in the Algiers suburbs. The production is modest: 2 heavy goods vehicles per day. This pace soon proves insufficient, and Berliet goes to the next step.

Berliet's highlight in Algeria: its factory

In 1956, before the Constantine Plan, Paul Berliet decided to build a Marius Berliet Automobile Foundation in Algeria. Various reasons are at the origin of this position: to reduce the transport costs of vehicles by assembling them on site and to consider Algeria as a link with Africa and therefore a base for expansion towards this continent.

To meet these objectives, Automobiles M. Berliet set up a subsidiary in May 1957: the Société Africaine des Automobiles M. Berliet, the S.A.D.A.B., better known as Berliet-Algeria.

In June 1957, in Rouïba, 27km from Algiers, a first section of buildings of 22,000m2 was built and a year later, the first vehicle fell from the Fondation de l'automobile Marius Berliet.

In October 1959, the second section was completed and covered 55,000m2. At the beginning of 1960, the workforce was 500 people, 80% of whom were Algerians. The gradual incorporation of parts manufactured on site is developing, as is the training of a skilled workforce. By the end, 5,000 trucks had been assembled. The rate is 6 units/day, the workforce 900 people.

After the signature of the Évian agreements, Automobiles M. Berliet continues to send dismantled trucks from France for local assembly, providing a wheel of activity at the Rouïba plant and covering African or French orders.

In 1967, the Algerian State created the National Society of Mechanical Constructions: SONACOME. Its purpose is to promote the mechanical industry in Algeria and holds a monopoly on the import of these products.

As part of the 1970 - 1973 four-year industrialization plan, aimed at implementing an independent industry with a high rate of local integration, SONACOME signed an agreement with Automobiles M. Berliet in , relating to the construction of a manufacturing of industrial vehicles and buses in Rouïba, on a license and technical assistance contract and on the sale of all of Berliet's facilities: in short, the supply of a "products in hand" factory. A specific training center was set up in Algeria in 1971: it will train 5,000 people including specialized workers, professional workers, employees, technicians, supervisors, engineers and executives. The average duration of training is 8 months in France and 10 months in Algeria.

In November 1974, it was the real start of the integration phase with the mechanical parts and the first truck made in Rouïba.

Assembly units increased from 1,540 vehicles in 1968 to 7,000 in 1974, while sheet metal, stamping and forge equipment began to be operational. 3,250 employees work in Rouïba, including 250 people from Automobiles M. Berliet as technical assistance. This local team is assured of the help of 500 technicians and engineers who, from Vénissieux, provide the necessary support to their Algerian colleagues. This association also results in a leverage effect caused by Berliet, which drives its suppliers and subcontractors from Rhône-Alpes to Algeria.

In 1977, the production of industrial vehicles will be doubled thanks to the extension of the industrial complex of Rouiba, built in 1971 with the technical collaboration of Berliet. The plant, which currently manufactures 4,300 five- to thirty-ton trucks and 250 buses, will increase these figures to 8,000 and 1,000 units per year.

During this time, Berliet became a subsidiary of the Régie Nationale des Usines Renault in December 1974, merged in 1978 with SAVIEM (Société anonyme de 1978. The two brands disappeared in favor of Renault in 1981.

If the story of Berliet ended like this, it remains for me that Berliet's DNA continues to survive in Algeria through models produced in this factory and whose genesis dates back to Berliet's time.

Comments